Imagine launching a new product only to discover critical flaws that could have been avoided. The market is unforgiving – a single oversight can mean the difference between market viability and discontinuation. This is where the essential value of prototyping in product development comes in.

Prototypes are central to product development because they ensure that brilliant ideas transform into flawless, market-ready products. By allowing teams to visualise, refine, and perfect their designs, prototyping and testing can save time, reduce costs, and enhance product quality.

This article examines the importance of prototyping and testing and how crucial it is in creating successful, user-friendly products.

Transforming ideas into reality

Prototyping is a fundamental step in product development that helps transform abstract ideas into tangible forms. It allows designers and engineers to visualise and refine concepts, making communicating ideas and gathering feedback easier. Prototypes come in various forms, each serving specific purposes throughout the development process.

Low-fidelity prototypes, such as sketches, wireframes, and basic 3D prints, serve as simple and cost-effective tools in the early stages of development. They enable teams to explore various ideas and concepts quickly. The real advantage of these prototypes lies in their flexibility—they can be easily adjusted based on user feedback.

Take wireframes, for instance: these two-dimensional visuals outline the layout of a web page or app interface. Designers use wireframes to map out a new mobile app’s structure, helping stakeholders grasp the basic flow before diving into detailed design work. This initial stage is critical, laying the groundwork for more refined prototypes and ensuring that core ideas are solid and integrate user insights from the start.

As the development journey unfolds, teams move on to medium-fidelity prototypes, which balance detail and adaptability. These might be more intricate digital models or semi-functional physical versions, allowing for targeted prototype testing of specific product features without the higher costs associated with high-fidelity models.

In software development, for example, medium-fidelity prototypes can involve interactive wireframes that let users navigate through an application, providing richer feedback than static images alone.

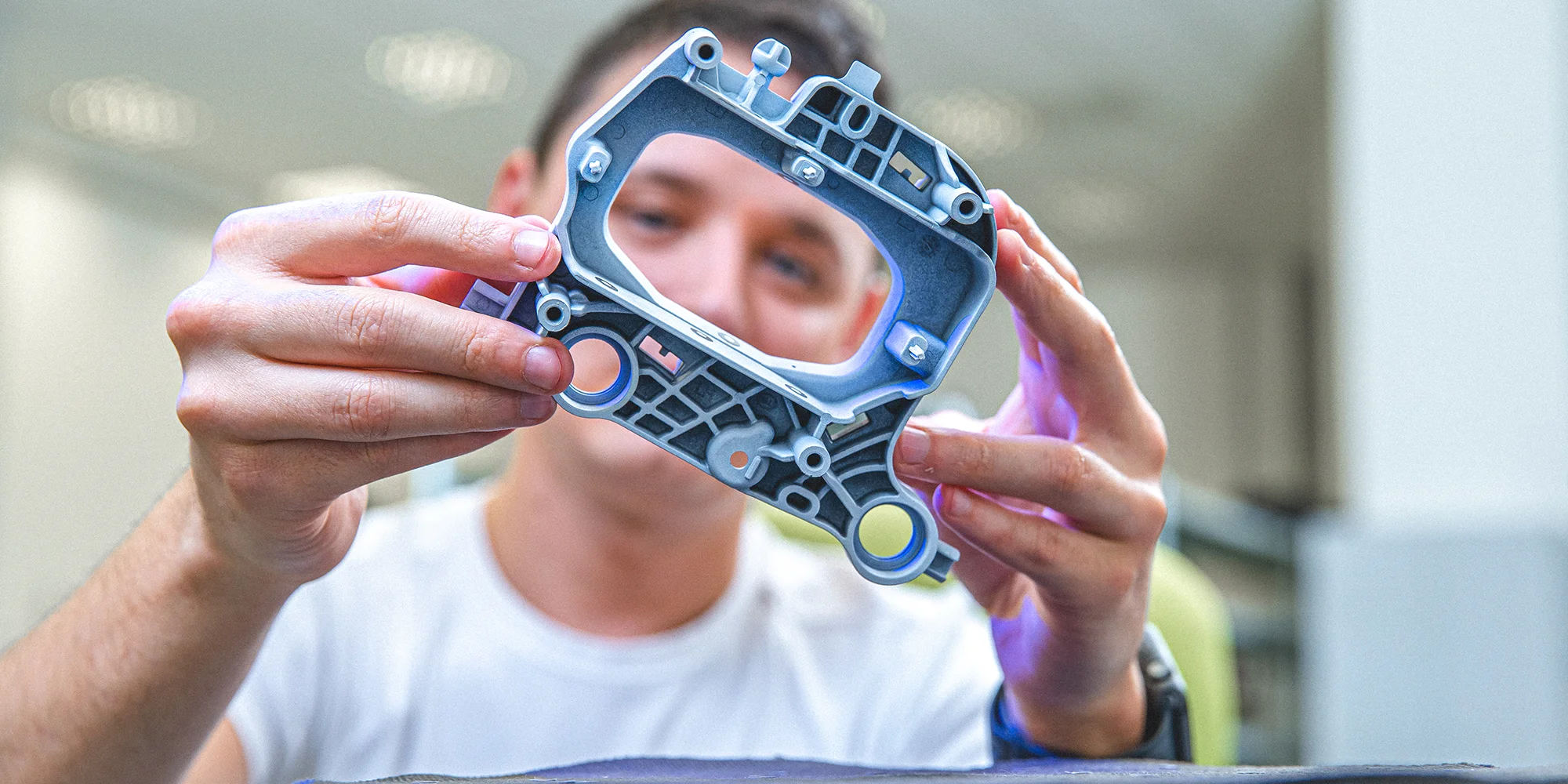

Finally, high-fidelity prototypes emerge as detailed representations that closely mimic the final product in both appearance and functionality. These prototypes come into play during the later stages of development and focus on usability, functionality, and aesthetics.

A high-fidelity prototype of a new medical device might be developed to evaluate its efficacy and ensure compliance with regulatory standards before entering full production. This stage ensures no detail is missed by allowing for comprehensive prototype testing of all product aspects, from visual appeal to functional performance and user interaction.

Spotting design flaws and usability issues early

One of the standout benefits of prototyping is the ability to catch design flaws and usability issues early on. By crafting prototypes and testing them at various stages of development, teams can spot and tackle potential problems before they escalate into costly fixes.

Different prototyping techniques serve unique purposes. Digital prototyping utilises software tools to create virtual models, while physical prototyping involves building actual models. Both methods are crucial at different points in the development process and for various types of products.

Digital prototyping shines in complex systems by allowing teams to quickly create and test multiple iterations. On the other hand, physical prototypes are key for evaluating the tangible aspects of a product.

Prototyping is inherently iterative. Each version of a prototype undergoes testing, with feedback driving improvements. This cycle continues until the product meets all its requirements. Take, for example, a consumer electronics company that develops a new smartphone. They might create several iterations, testing each to refine its design and functionality based on user insights. This iterative approach ensures that potential issues are thoroughly addressed, resulting in a polished final product.

Navigating the iterative testing cycle

The iterative prototype testing cycle is essential for refining products to meet functional specifications and user needs. Teams can effectively tackle potential issues by continuously assessing and enhancing prototypes using real-world insights, leading to a more polished and user-friendly final product.

Functional testing is key here, ensuring the product operates as intended. This involves checking all features and functions to pinpoint any bugs or issues that may arise. For instance, a software company may conduct functional testing on a new application to verify that every feature works seamlessly. This type of testing is vital for identifying problems that could impact performance and the overall user experience.

Conversely, user testing focuses on gathering feedback from actual users to understand their preferences and requirements. This input is invaluable for making design choices that enhance usability. Imagine a furniture company developing a new chair: by creating prototypes and inviting users to test them, they can collect insights on comfort and practicality. Incorporating this feedback helps ensure that products align with the expectations of their target audience.

Ultimately, thorough prototype testing paves the way for a successful market launch. This process includes validating the product against regulatory standards and market requirements. For example, a new medical device must undergo rigorous testing to achieve UKCA or CE marking before it can be marketed. Ensuring market readiness is not just about compliance; it’s also about making sure the product stands out and appeals to consumers.

Accelerating success through time and cost savings

Effective prototyping and testing can save time and money in the product development journey. By identifying and resolving issues early on, companies can avoid expensive changes later in the process.

Catching design flaws and usability problems during the prototyping phase can lead to significant cost savings. Addressing issues at this stage is far less expensive than making adjustments after production has kicked off. Take the automotive industry as an example: a car manufacturer might use prototypes to test new features, allowing them to make tweaks before entering mass production. This proactive investment in prototyping helps companies dodge the hefty costs linked to post-production modifications and recalls.

Prototyping also boosts time efficiency, enabling teams to tackle challenges quickly and keep the development process moving. For instance, a tech startup might employ rapid prototyping techniques to create and test a new gadget, getting it to market faster. By swiftly identifying and addressing any hiccups, teams can maintain their momentum and stick to their development timelines.

Boosting quality with design for excellence

Prototyping and testing are vital in boosting product quality to ensure the final outcome meets all functional, aesthetic, and user needs.

Design for Excellence (DfX) is at the heart of this process, which encompasses key elements like manufacturability, serviceability, cost, reliability, and quality. By keeping these factors in mind throughout development, teams can craft products that truly excel. For example, a consumer electronics company might apply DfX principles to design devices that are easy to manufacture, dependable, and budget-friendly. This comprehensive approach guarantees that every aspect of the product is fine-tuned for optimal performance.

Verification and validation processes are equally important, serving as checks to meet regulatory standards and uphold product quality. Verification confirms that the product aligns with all specified requirements, while validation ensures it meets user expectations.

Take a medical device manufacturer as an example – they would utilise rigorous verification and validation methods to ensure compliance with industry standards and user safety. By thoroughly testing and validating their products, companies can assure their customers of top-notch quality and adherence to essential regulations.

The real-world impact of prototyping best practices

To illustrate the benefits of product testing and prototyping, consider the development of a new wearable fitness device. The team starts with low-fidelity sketches and wireframes to outline the basic design and features. These initial prototypes help gather feedback from stakeholders and potential users, allowing the team to refine their ideas.

Next, they create medium-fidelity digital prototypes to test the device’s user interface and functionality. These prototypes are used to conduct usability tests to identify any issues with navigation and interaction. Based on the feedback, the team makes adjustments and creates high-fidelity physical prototypes.

The high-fidelity prototypes are tested in real-world conditions to ensure they perform as expected. This stage involves:

- Functional testing to verify that the device accurately tracks fitness data.

- User testing to gather feedback on comfort and usability.

- Market readiness testing to ensure it meets regulatory standards.

By following this iterative process, the team can identify and address issues early, saving time and reducing costs. The final product is a high-quality, market-ready device that meets user needs and exceeds expectations.

Elevate your product development with 42T

The importance of prototyping and product testing cannot be overstated. They are not just steps in the product development process—they’re your best allies in creating exceptional products that resonate with users. By investing time and effort upfront to refine your ideas and spot potential issues, you set the stage for a successful launch that meets market demands.

At 42T, we embrace an agile and risk-based approach to product development, tackling the biggest challenges first. Our commitment to thorough prototyping, testing, and adherence to regulatory standards ensures that your products are innovative and market-ready.