With energy efficiency improvements such a core part of the net zero strategy and providing a dual benefit with economic savings, it is becoming increasingly clear that solutions like heat recovery are effective options for businesses.

Climate change is likely to be the single biggest challenge our society will face this century. It has already entered the global consciousness on a long-term basis and is affecting both the public and the private sector heavily.

The solutions to achieve the ambitious targets to reach net zero by 2050 are varied and currently there is a large degree of uncertainty on how best to reach these targets.

Despite this, some overarching solution types have been identified which are likely to make a large contribution. Energy efficiency improvements are expected to contribute around 40% of the emissions reduction needed by 2050, according to the IEA Sustainable Development Scenario.

The primary objective of this route is to reduce the energy wasted with performing an essential task. One very common example of this is heating. Many industrial processes require large amounts of heat, such as product forming, chemical reactions or drying. These processes are very rarely able to impart heat at a high efficiency to a product or substance.

Even if the heat delivery is targeted, the products will not need to retain all the energy that has been imparted. This is where heat recovery can aid organisations.

Heat recovery takes the waste heat from an essential process and uses that heat for other processes. This happens by transferring the energy from one fluid to another.

What is low-grade heat?

Waste heat utilisation at high temperatures can be relatively straightforward. Provided the temperatures are not high enough to damage a recovery unit, the heat can be used for a wide variety of processes, even electricity generation.

When the heat at the exhaust is leaving at 250 degrees or below, this can be more challenging as it limits the further processes that this heat can be used for and can make recovery more difficult.

Heat at this low temperature is known as ‘low-grade heat’. Common sources of low-grade heat include the flue gasses from boilers, the exhaust from ovens across various industries, and dryers.

How much low-grade heat is there?

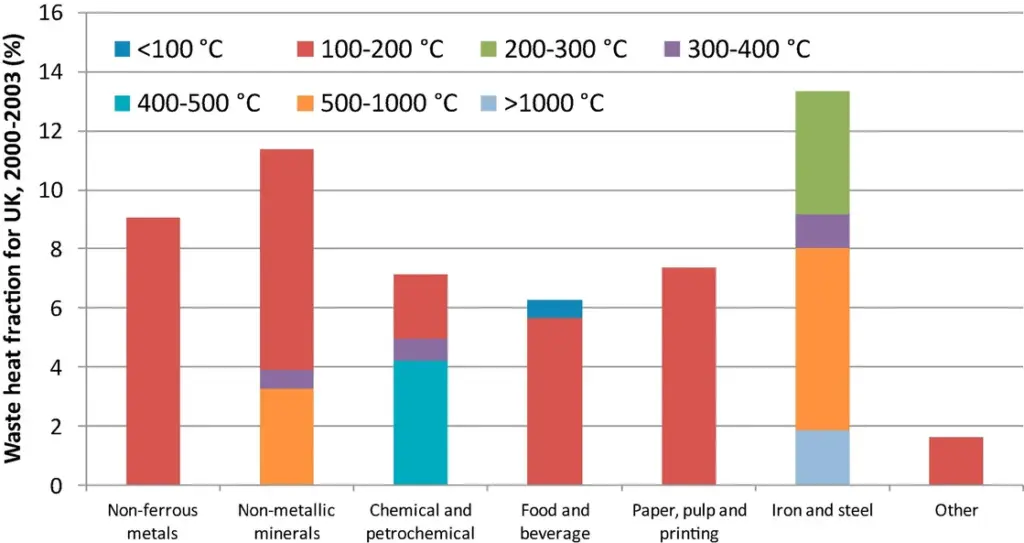

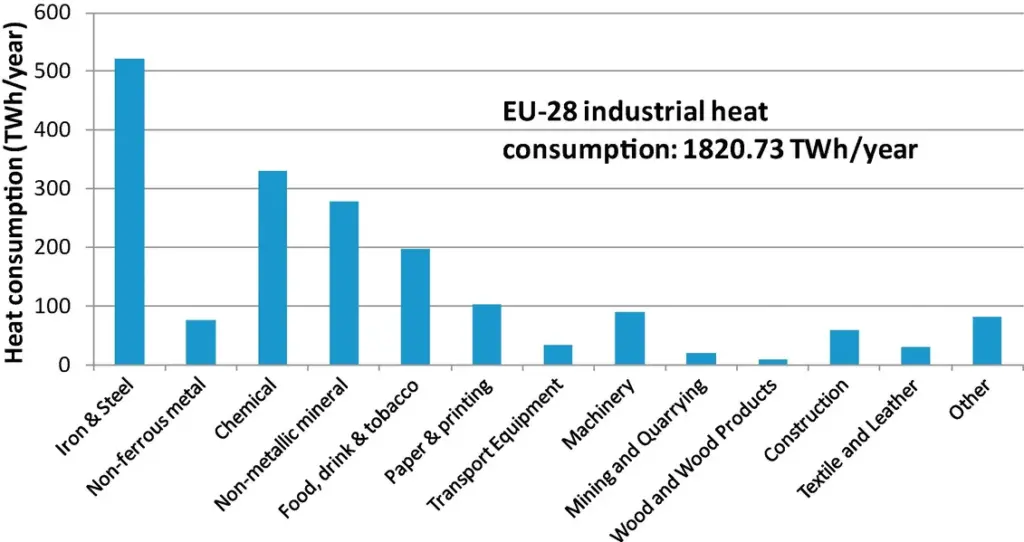

As Figure 1 shows, up to 50 percent of all heat emitted in the UK falls within the low-grade heat temperature bracket.

There are some key industries that emit more than others, however. Figure 2 demonstrates that there is significant potential in many industries to capitalise on heat exhausted to atmosphere.

As the price of energy continues to soar, there is significant value to be had in recapturing some of this lost heat.

Energy cost savings & straightforward to do

Efficiency improvements such as heat recovery have a dual benefit for organisations. Reducing the overall energy consumption of a facility has a cost benefit. With the cost of fuel rising and source uncertainty an issue going into the future, reducing the impact that price fluctuations can have on an organisation is highly desirable.

Additionally, reducing the impact an organisation or facility has on the climate by resource reduction future-proofs an organisation against net zero regulation and carbon pricing. The consumer appeal of products produced using more sustainable means or with superior ‘green’ credentials also cannot be overlooked.

When compared to other net zero solutions, heat recovery is a change that in many cases can be retrofitted simply without heavy interference with existing equipment. Retaining existing assets makes this option very attractive.

What options are there for waste heat?

The first consideration for those interested in recovering heat is what to do with the heat once it is recovered. If the demand is lower, the recovered heat will have to be dumped, resulting in the same or greater waste than before.

Common uses for the lower grades of heat can be for processing hot water, district or domestic heating and product pre-heating. Less common but potentially attractive applications for this heat could be electricity generation or thermal storage for those who do not have an immediate demand for low-grade recovered heat.

Electricity generation has been gaining interest for low-grade heat, with advances in non water-based generation such as the Organic Rankine Cycle (ORC) and the Kalina cycle. Both use fluids with advantageous characteristics for lower temperature heat. The ORC uses a working fluid with a boiling point low enough to operate with the temperature of the heat available.

Although its simplicity makes the ORC attractive, it delivers low efficiencies when compared to other methods of electricity generation. The Kalina cycle uses a dual fluid with different boiling points as the working fluid. This provides greater efficiencies than the ORC, however with a greater complexity.

To decouple the common problem of supply and demand mismatch between the exhaust and the secondary heat requirement, thermal storage can be used. The simplest of these can take the form of large tanks of well insulated water that can be kept for hours until the demand is required.

Phase change thermal storage gives the option of storing larger amounts of energy at lower temperature than sensible heat-based thermal storage, if implemented correctly.

Chemical reaction-based systems can be used for longer term thermal storage, as reaction products can have energy applied, separated and then brought back together, releasing the heat again.

What needs to be considered?

Almost all the options for heat recovery require a heat exchanger to transfer the heat from the exhaust fluid to a working fluid to be used for the secondary heating application. There are various designs of heat exchanger that offer advantages for different applications.

For example, some heat exchanger types can be very resistant to blockages or fouling, but the design of these can result in lower efficiencies. Additionally, the space to house the heat exchanger or the working fluids can be a significant constraint.

The selection and sizing of the heat exchanger is an important design decision that is required. The constituents of the gas stream, fluid flow rates, temperatures and output requirements to the working fluids are all key design parameters.

Benefits vs. outlay

With energy efficiency improvements such a core part of the net zero strategy and providing a dual benefit with economic savings, it is becoming increasingly clear that solutions like heat recovery are effective options for businesses.

The benefits are quickly becoming dominant compared to the initial outlay from equipment as regulations tighten and energy prices soar. With some consideration around the utilisation of the heat and the heat recovery system, business can play a vital part in the contributions to net zero.

If you would like an independent insight into how you could reduce waste and improve the sustainable credentials of your products, get in touch with us.