Background

In pharmaceutical manufacturing, line clearance — the process of ensuring no materials from a previous batch remain — is a critical but often manual step. It’s time-consuming, labour-intensive, and a bottleneck to production efficiency.

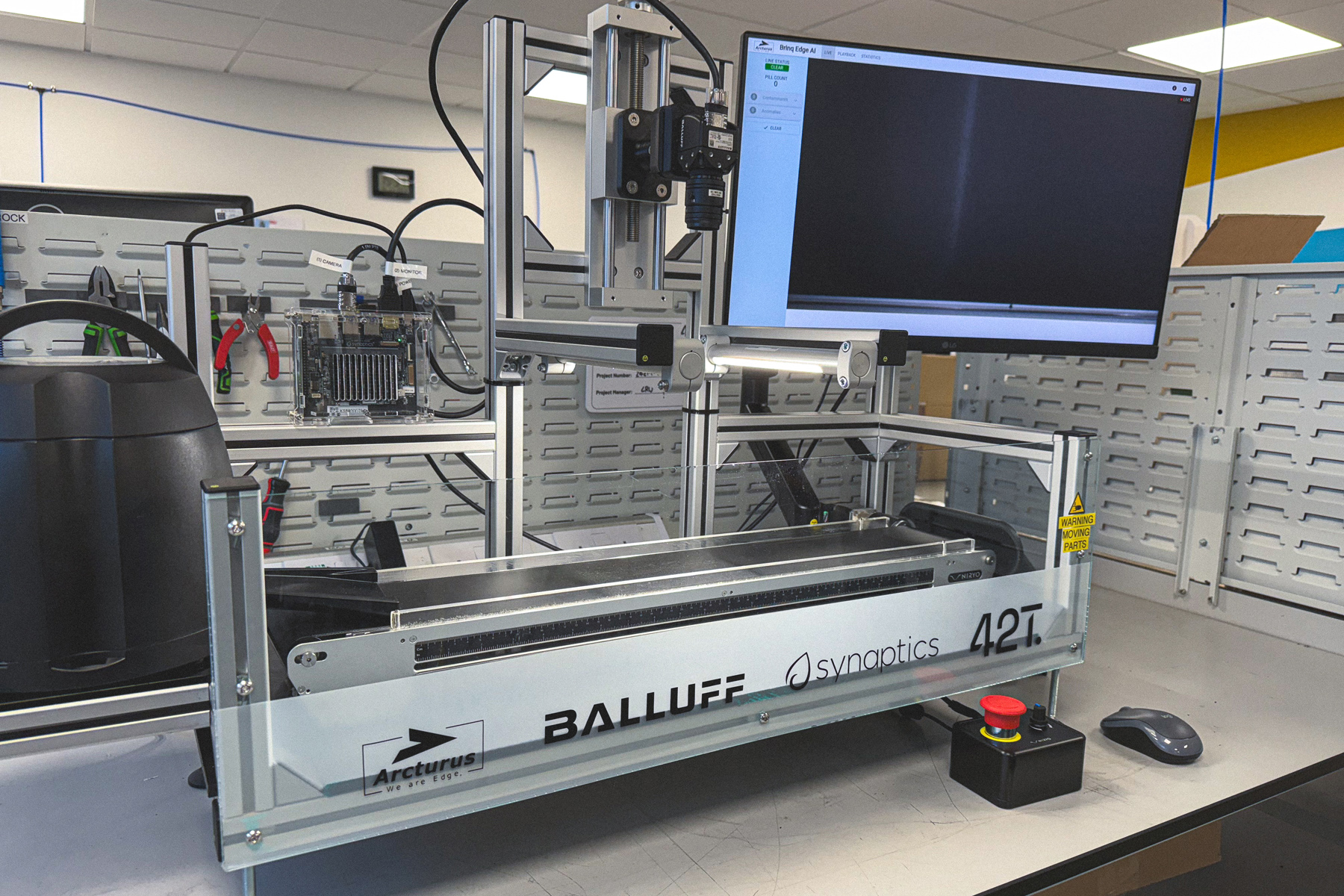

That’s why 42 Technology, in partnership with Synaptics, Balluff and Arcturus Networks, developed the Edge AI Line Clearance Demonstrator, a proof-of-concept system showcasing how embedded AI at the edge can transform this essential process.

By combining Synaptics’ Astra™ IoT processing platform, Balluff’s industrial image acquisition solutions, Arcturus Networks deep learning models and 42T’s expertise in AI, vision systems and industrial engineering, the team created a system that balances performance and cost to provide a scalable real-time object and anomaly detection system. The open development environment enabled by Synaptics combined with the suitability of hardware for industrial applications, provides a commercially viable approach to address the challenges of automated line clearance checks.

What we did

The final system showcases how real-time object detection, with immediate alerts and recording of anomalies, can be performed at the edge, close to the source, without requirements for cloud computing or additional compute hardware — all built around real-world industrial instrumentation

Behind the scenes, this demonstrator was a tightly coordinated engineering effort:

- CAD design and prototyping

- UI design & development

- Astra hardware integration

- Custom framework fabrication

- Optimisation of vision pipelines and ML models

- Final assembly and testing

Results for our client

When applied to multiple locations across a production line, this approach could be deployed to enable simultaneous checks of each location, estimated to achieve up to 85% time savings compared to manual processes.

Proven results

Faster, smarter, more scalable

The demonstrator simulates a pharmaceutical inspection line where pills pass along a conveyor and are imaged by a Balluff industrial camera. Embedded AI models, running on the Astra device, analyse these live images to perform the following:

- Line Clearance – the detection of material on the line/line in use and line clear states

- Materials Analysis – the detection, count or flow rate of material under inspection

- Anomaly – the detection of foreign/unknown material on the line

- Contaminant – the detection of incorrect material on the line

- Defect – the detection of material that does not meet standards

Collaboration is the catalyst

This project highlights the strength of cross-industry collaboration, blending AI-edge technology with pharmaceutical production challenges. As described in our joint press release, the partnership with Synaptics, Balluff and Arcturus Networks opens the door to broader innovation in smart manufacturing.

Next steps: from concept to real-world impact

This is just the beginning. The Astra Line Clearance Demonstrator is designed for scalable deployment, with future enhancements already in the pipeline, including expanding the platform to be deployed alongside existing automation and industrial PLC systems, expansion of the autonomous deep learning capabilities for on premises model training and suitability for a wider range of imaging systems for deployment in a multiple production environments.