Discover how simulation modelling transforms engineering and manufacturing by reducing risk, accelerating innovation and supporting better decisions. From predictive analysis to system optimisation, learn how virtual testing helps teams develop faster, smarter and with greater confidence.

Why simulation modelling matters in engineering and manufacturing

If you’re responsible for product development, quality control or programme delivery, you’ve likely faced challenges where physically building and testing isn’t practical, whether due to cost, complexity or time constraints. For example, building as many physical variations as needed or creating environmental conditions and/or test durations that aren’t practical. Being able to understand and confidently predict system behaviour gives teams a clear advantage.

That is where simulation proves its value.

Simulation in engineering and manufacturing involves creating digital models of products, systems or processes to predict how they will perform under real-world conditions. These models often incorporate timings, resources, rules and constraints and provide a virtual environment that mirrors key aspects of the real-world process. Simulation plays a growing role in sectors such as food production, energy and/or industrial devices, medical devices, consumer products and packaging, where efficiency, safety and precision are business critical.

When used effectively, simulation becomes a powerful tool for exploration and optimisation. It enables teams to test ideas, compare scenarios and move forward with clarity. Within a broader development workflow, simulation enhances design thinking, accelerates progress and strengthens technical outcomes.

This article explores what simulation is, when it delivers the most value and why its effectiveness increases when embedded into a collaborative, multidisciplinary approach. It also shows how 42T applies simulation in real-world manufacturing and product development contexts as part of robust engineering programmes that deliver practical results.

What is simulation modelling?

At its core, simulation is a form of mathematical modelling used to virtually test scenarios and predict key behaviours. By assessing a range of constraints and scenarios (potentially not practically testable) with this mathematical framework, teams can explore, refine and optimise designs early in development.

Simulation modelling can be as simple as running a few equations to capture the behaviour of a specific part or process. At the other end of the spectrum, it can involve building detailed, visually rich digital representations of entire systems with multiple interacting physics and control layers. Most applications fall somewhere in between, tailored to the complexity and goals of the project.

This approach supports informed, evidence-led engineering. It helps teams answer critical design questions, investigate edge cases, and evaluate trade-offs quickly and safely. Rather than replacing physical prototyping, simulation improves it by narrowing down the field of options and focusing time and resources where they matter most.

One of the most valuable uses of simulation is predictive analysis. This involves using models to forecast trends, test scenarios and support confident decision-making. By simulating how a system will respond to different inputs, conditions or usage patterns, engineers can anticipate challenges, evaluate alternatives and make evidence-based choices throughout the development process.

There’s no single simulation method that fits every engineering challenge. The right approach depends entirely on the question you’re trying to answer. At 42T, simulation is used across manufacturing, product development and systems engineering, with different methods tailored to specific performance goals, physical behaviours or project constraints.

Here are ten advanced modelling and simulation techniques we commonly apply at 42T:

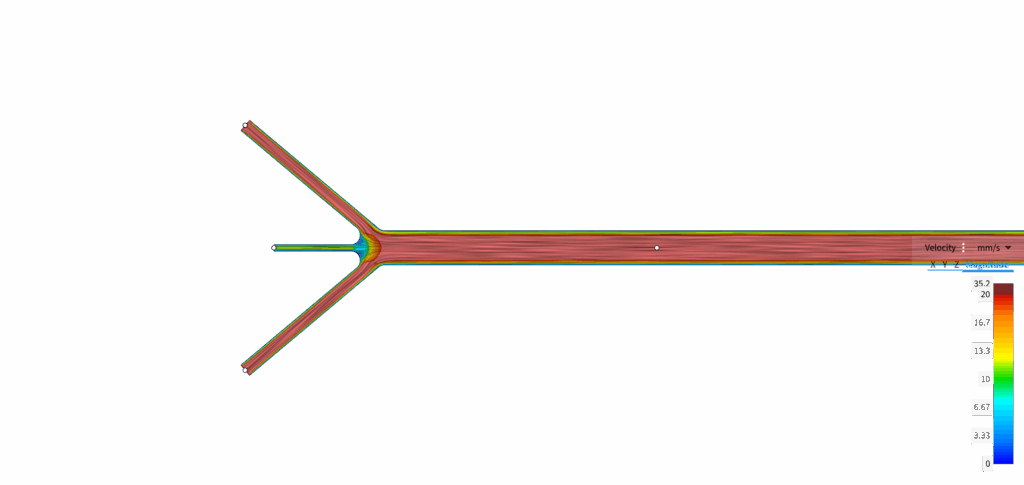

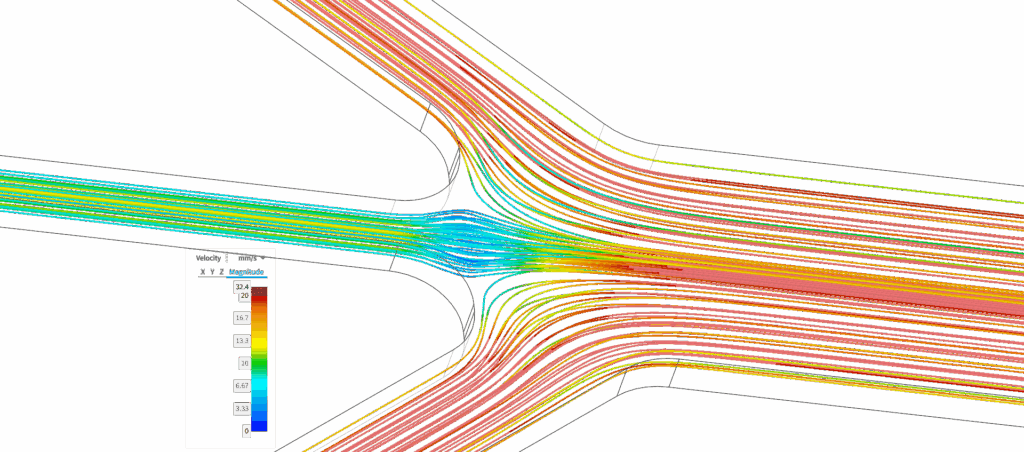

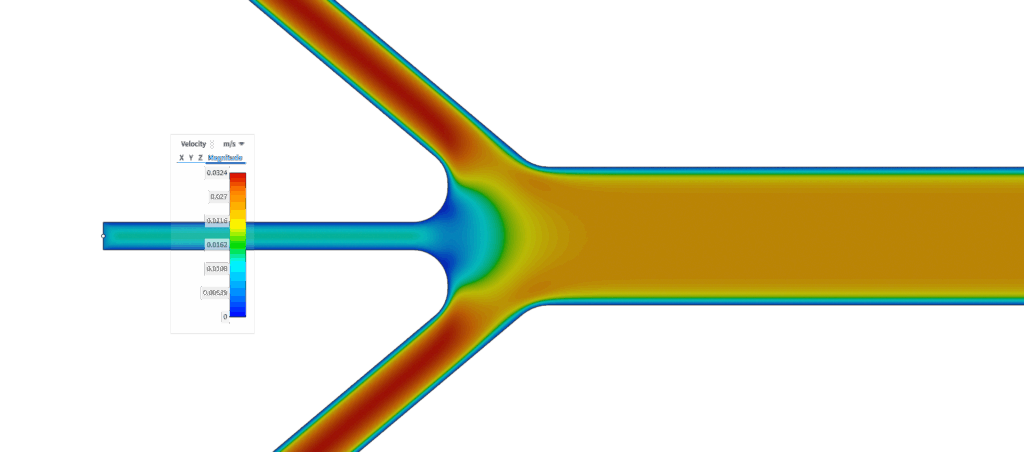

- Computational fluid dynamics (CFD): Used to model the behaviour of liquids and gases. It helps optimise flow paths and characteristics (e.g. turbulence levels), and manage thermal conditions, supporting better cooling, ventilation and fluid performance in complex systems.

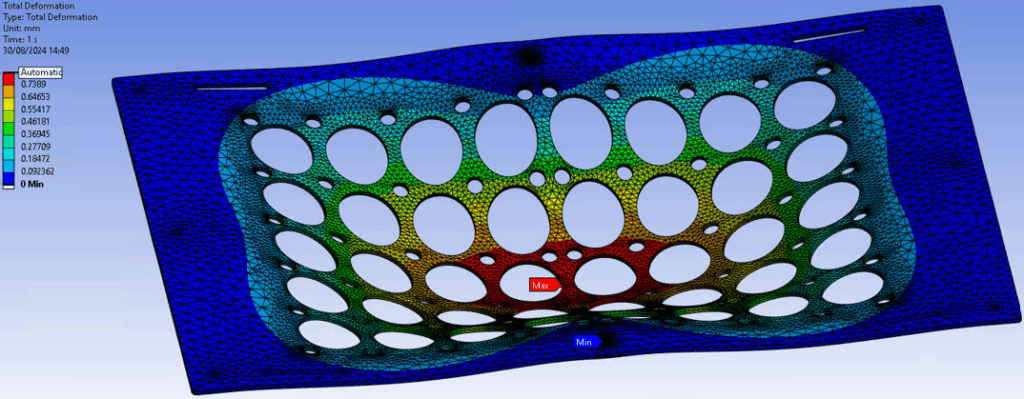

- Mechanical / structural simulation: Applied to assess structural behaviour under load. It predicts stress, strain and deformation in components, allowing teams to validate strength, optimise material use, and improve durability before physical testing. Generally done using FEA modelling tools.

- Multiphysics simulation: Integrates multiple physical domains, such as thermal, fluid, and mechanical, into one simulation. It’s ideal for analysing systems where physical interactions are tightly coupled and can’t be studied in isolation.

- Analytical modelling: Uses simplified equations and physics to gain quick, insightful approximations of system behaviour. It’s particularly useful in early design phases or when building fast-running tools for iterative use.

- Numerical modelling: Applies advanced mathematical techniques to simulate complex systems with high precision. This approach supports detailed investigation of dynamic processes, system responses, or geometry-sensitive behaviours.

- Bespoke mathematical modelling Builds tailored models in platforms like Python or MATLAB to suit unique project needs. These bespoke tools enable faster iteration, deeper insight, or more specialised functionality than off-the-shelf software allows.

- Electromagnetic simulation: EM is arguably our largest suite of codes and models. Amongst others, it covers the analyses of electromagnetic field behaviour, particularly for antenna design, EMC/EMI performance, and signal integrity. This helps engineers address interference and compliance challenges in electronic systems.

- Thermodynamics and heat transfer: Focuses on the movement of heat within and between materials. Simulations in this area are used to optimise thermal performance, manage hotspots, and improve energy efficiency in both products and processes.

- System-level modelling: Models complete systems by combining mechanical, electronic, fluidic or control subsystems into a unified framework. This helps predict overall functionality, control behaviour and real-world performance.

- Optics: We work with a variety of techniques and tools to model various optical systems. This includes ray tracing (sequential and non-sequential), coherent propagation and custom simulation of more novel systems. This has enabled us to develop cutting-edge optics technologies for our clients.

These methods can be used individually or combined to support accurate, actionable insight throughout the development process, from feasibility studies to detailed design and final validation.

“All models are wrong, but some are useful.” This well-known quote from George Box highlights a key point: every simulation involves some simplification. The aim is not to perfectly replicate reality but to focus on the most influential variables and produce insights that support real progress. Effective simplification depends on engineering judgement, relevant data and a clear understanding of practical constraints.

What can simulation modelling help you achieve?

Used effectively, simulation modelling enables engineering teams to solve technical challenges earlier, make faster progress with fewer physical prototypes, and improve system performance over time. It supports better decisions at every stage, from initial concept development through to production refinement.

Risk mitigation: Identify challenges before they escalate

Every engineering project carries some level of uncertainty. Being able to anticipate risks early is essential to avoid disruption and costly changes.

Simulation provides that foresight. Structural analysis might reveal stress concentrations, or a CFD model might show uneven temperature distribution across a system. These insights allow engineers to address potential failures while changes are still manageable, thereby increasing reliability and design confidence. This is a core application of simulation in risk mitigation: identifying and addressing potential failures before implementation.

Cost-effective prototyping: Refine faster, waste less

While physical prototyping remains important, it’s rarely practical to build and test every concept variant. Simulation modelling offers a faster, leaner alternative.

Using simulation early in the design process enables faster decisions, fewer physical prototypes, and better system understanding. Teams can test materials, geometries, tolerances and boundary conditions, such as load and flow rate virtually, quickly comparing and refining ideas without incurring tooling or material costs.

This use of simulation enables cost-effective prototyping by reducing the need for physical testing through digital modelling while also enabling early-stage predictive analysis. It also supports more sustainable development, allowing teams to explore more options with less waste. It enables rapid iterative development, too, where small changes can be evaluated and adjusted without the delays of physical builds.

System optimisation: Maximise efficiency and performance

ISimulation helps improve the performance of wider systems, from production lines and energy transfer to control architectures and automated processes. Using dynamic simulation or process simulation, engineers can assess how systems behave under different inputs or sequences and identify performance limitations.

This systems-level approach is widely applied across sectors. Case studies from Imperial College London show how simulation methods such as FEA and CFD are used to solve performance and integration challenges in industries such as aerospace and biomedical engineering.

In manufacturing, simulation supports layout planning, energy optimisation, product consistency and machine uptime. For example, a packaging line might be modelled to assess how line speed affects fill accuracy. A thermal system could be simulated to improve temperature control or reduce energy loss.

In all these scenarios, simulation plays a critical role in system optimisation by improving efficiency, quality and performance in manufacturing processes.

Decision-making: Clarity, speed and alignment

Simulation also improves how teams collaborate. By visualising performance and comparing design variants, engineers, designers and programme leads can evaluate trade-offs using shared evidence.

This supports stronger decision-making, especially when teams are choosing between options or making changes mid-project. It also enables better multidisciplinary collaboration, reducing misunderstandings across teams and aligning technical choices with broader programme goals. As a result, simulation supports decision-making by enabling data-driven decisions for engineering challenges.

When to use simulation in product development and manufacturing

The value of simulation modelling is defined by both how it’s used and when it’s applied. Introducing simulation at the right stage in a development programme helps accelerate progress, reduce risk, and avoid costly changes downstream.

Early-stage product concepts: Validate before you build

Concept validation is one of the most effective applications of simulation. It allows teams to start testing concepts before investing in prototypes. By doing so, they can explore feasibility, evaluate alternatives and understand how different design decisions will affect performance, usability or compliance.

This supports smarter, evidence-based decision-making, often saving weeks of effort and reducing unnecessary prototyping.

Research and development: Test and iterate virtually

In R&D, simulation enables teams to test new ideas virtually and refine concepts alongside experimental work. It plays a valuable role in assessing feasibility and improving new technologies, particularly when physical testing is limited or when working at the edge of established design space.

Simulation supports iterative development, allowing assumptions to be adjusted as data is collected and helping physical trials focus on the most valuable outcomes. It’s particularly effective in multiphysics environments, where multiple physical forces or interactions must be modelled together.

Quality control: Ensure process assurance and compliance

In later-stage development and manufacturing, simulation strengthens quality and consistency. For example, process simulation can assess how a component responds to sterilisation or how raw material variation affects forming.

According to a case study from the Royal Academy of Engineering, similar modelling techniques have been used in UK healthcare to simulate patient flows, improving resource allocation and patient outcomes.

By embedding virtual models into quality strategies, manufacturers can pre-empt defects, reduce variation, and implement robust processes from the outset. In this way, simulation helps predict defects and ensure consistency, particularly in regulated or high-volume manufacturing environments.

Project planning: Forecast, align and reduce costly delays

From a commercial perspective, simulation helps project teams plan with greater confidence. Feasibility simulations clarify requirements and constraints early, helping prevent delays and late-stage redesigns.

Predictive analysis is especially useful at this stage, helping teams forecast the implications of different technical or commercial pathways with greater confidence. Simulation also supports stakeholder alignment, enabling teams to evaluate options objectively and set realistic expectations around technical outcomes, costs and timelines. It contributes to reducing costs and improving project timelines, especially when used as part of an integrated programme.

Maximising value: Integrating simulation into your engineering workflow

While simulation modelling is powerful on its own, it becomes even more effective when integrated into a broader engineering process. When simulation is combined with other engineering tools, development pathways and testing data, it delivers insights that lead to faster progress and better outcomes.

This approach supports true multidisciplinary collaboration, allowing engineers, designers and analysts to work with aligned data and shared goals.

Combining simulation with real-world data

Simulation models become significantly more valuable when grounded in real-world data. Measurements from sensors, test rigs or previous products can improve model accuracy and relevance, helping teams align virtual results with actual system behaviour. It is best practice for almost all simulation setups/approaches to be validated using real-world data. This can either be done using existing test data and a simulation scenario to match or set up bespoke test(s) to validate the simulation approach. Simulation validation increases confidence in predictions and helps refine models for future use.

For example, temperature data from a sterilisation cycle might refine a thermal model of a medical device. Motion data from a packaging line might help adjust a dynamic simulation of product handling. These feedback loops support smarter, faster iterative development and enable multiple cycles of refinement across both digital and physical domains.

Adding digital twins

Simulation also forms the foundation of digital twin development: dynamic, data-driven models that mirror real-world systems. By linking simulation models with live sensor inputs, teams can build digital twins that reflect current operational conditions in real time. This allows for continuous monitoring, predictive maintenance and more agile responses to system changes, making it easier to optimise performance and reduce downtime throughout a product’s lifecycle.

Adding artificial intelligence

When simulation is combined with artificial intelligence and machine learning, its potential expands even further. AI techniques can automatically explore large design spaces without the need for parameterised models, uncover performance patterns and learn from historical results to predict future simulation results with high level confidence. Only the promising design needs to be taken to full analysis to verify prediction. AI can also enhance setup by intelligently adapting to the most appropriate algorithms and physics models e.g. switching to best turbulence model during analysis instead of needing to predict expected dominant turbulence type and lock in the corresponding physics model, increasing accuracy and reducing need for repeats. This enhances design space exploration, speeds up analysis and supports better decision-making, particularly in complex, data-rich or time-constrained engineering environments.

Accelerating innovation through collaboration

Simulation brings clarity to complex problems, especially in projects involving mechanical, electrical and software elements. When teams can view and interrogate the same results, communication improves, trade-offs become clearer and collaboration becomes more effective.

This is the foundation of strong multidisciplinary collaboration, where decisions are based on shared evidence rather than assumptions.

Moving beyond static reports

Some organisations still approach simulation as a service: a specialist team runs a model and sends back a report. But this limits its potential. Simulation works best when it’s part of an ongoing dialogue and embedded within a rounded programme of work, rather than treated as a standalone service or a one-off report on a pre-defined scenario.

This way of working makes simulation a live asset, a tool that supports decision-making throughout the development cycle, not just a snapshot delivered at a single point in time.

A platform for long-term efficiency

Simulation also delivers lasting value after launch. A validated model can support future process changes, product upgrades, or maintenance planning. A production line simulation might later inform a layout change or scale-up strategy.

By treating simulation as a live knowledge base, teams extend its value far beyond initial development and support long-term system optimisation.

Real-world applications in manufacturing

Simulation delivers measurable value in real engineering projects by helping teams improve performance, reduce risk and accelerate development. At 42T, simulation is routinely applied across manufacturing, packaging and healthcare to solve complex problems and support informed design decisions.

In one example of medical device development, simulation modelling was used to test how a device would behave under thermal and mechanical loads before any components were built. This approach helped reduce physical iteration, align the design with manufacturing requirements and mitigate risk before validation. It also supported regulatory confidence by enabling earlier verification of performance criteria.

Another project involved the development of a small-batch RNA vaccine manufacturing system. 42T used simulation to optimise fluidic pathways, mechanical design and control system interactions. Modelling helped the team improve cleanability, ensure reliability under operational conditions and support process validation, accelerating progress toward clinical-scale readiness.

These examples demonstrate how simulation, when embedded within a wider development programme, contributes to innovation, efficiency and better technical outcomes.

Why 42T? Integrated simulation expertise that delivers results

At 42T, simulation is never seen as an end in and of itself but used as a tool to drive forward technological and commercial goals. It is embedded within a comprehensive engineering workflow that spans product development, testing and innovation. Our approach combines simulation with sensing data, experimental results and physical prototyping to build solutions that are both technically robust and commercially grounded.

We specialise in solving system-wide challenges, not just modelling isolated components. This enables us to support clients with tightly integrated systems, multiphysics interactions and high-stakes technical constraints, whether in industrial, energy, manufacturing, healthcare, packaging, or food and drinks.

Our team brings together a broad mix of engineering and scientific expertise, enabling smooth multidisciplinary collaboration from concept through to delivery. Our integrated simulation team works collaboratively across disciplines to resolve complex technical issues, accelerate decision-making and develop more effective products and processes. This joined-up way of working ensures that simulation drives insight and value throughout the development cycle.

Simulation at 42T supports clients in multiple ways, from early-stage risk mitigation, through to cost-effective prototyping, and ongoing system optimisation. Our team tailors each model to the question at hand, ensuring the right level of complexity and integration to support confident, evidence-based choices. Sometimes, a quick indicative physical test can be a better/quicker fit for effort vs. value of information options over simulation. Because we do both, we can advise the client and take the most appropriate approach to deliver outcomes and value.

With ISO 9001:2015 and ISO 13485:2016 accreditations, and experience across healthcare, manufacturing and energy sectors, 42T is trusted to deliver reliable outcomes on business-critical projects.

Turning insight into action

Simulation modelling gives engineering and manufacturing teams the tools to explore ideas, reduce uncertainty and make confident, evidence-based decisions. It involves building virtual models of real-world systems to predict performance, evaluate alternatives and optimise outcomes before anything is physically built.

Simulation adds value at every stage of development, from predictive analysis and concept testing to process optimisation and long-term system improvement. When integrated into a wider programme of design, testing, and analysis, it enhances collaboration, accelerates innovation, and strengthens technical decision-making.

For teams facing complex engineering challenges, simulation can unlock smarter ways to work, helping reduce risk, improve efficiency and deliver better outcomes faster, especially when combined with sensing, prototyping and real-world data.

Ready to explore the value of simulation modelling in your next project? Contact our multidisciplinary team to get started.