42 Technology (42T) has joined forces with industry leaders in machine vision, edge AI silicon and software – Balluff, Synaptics and Arcturus Networks – to help develop and demonstrate a breakthrough approach for AI-powered automated line clearance in pharmaceutical manufacturing.

The four partners have pooled their technology expertise and application knowledge to develop a lower cost, flexible, and scalable alternative to existing AI-powered automated technologies. Most dedicated systems designed to automate line clearance processes are too expensive for widespread use because of their high hardware costs, complex integration, and the need for extensive training on production lines.

The new approach, which has been developed with inputs from some of the world’s leading pharmaceutical manufacturers, addresses these challenges by using a fully autonomous, deep-learning AI platform. Unlike conventional systems, the inspection system is designed to enable in-process learning without the need for lengthy setup and training routines on live production lines.

Line clearance checks are critical in pharmaceutical manufacturing to ensure that all materials, products, labels and records from a previous batch have been completely removed before starting the next one. The process involves multiple manual inspections, often taking up to one hour between batches, which significantly impacts production efficiency, especially as the industry shifts towards personalised medicine and smaller batch sizes. Industry experts estimate up to 85% time savings with automated line clearance versus current manual checks.

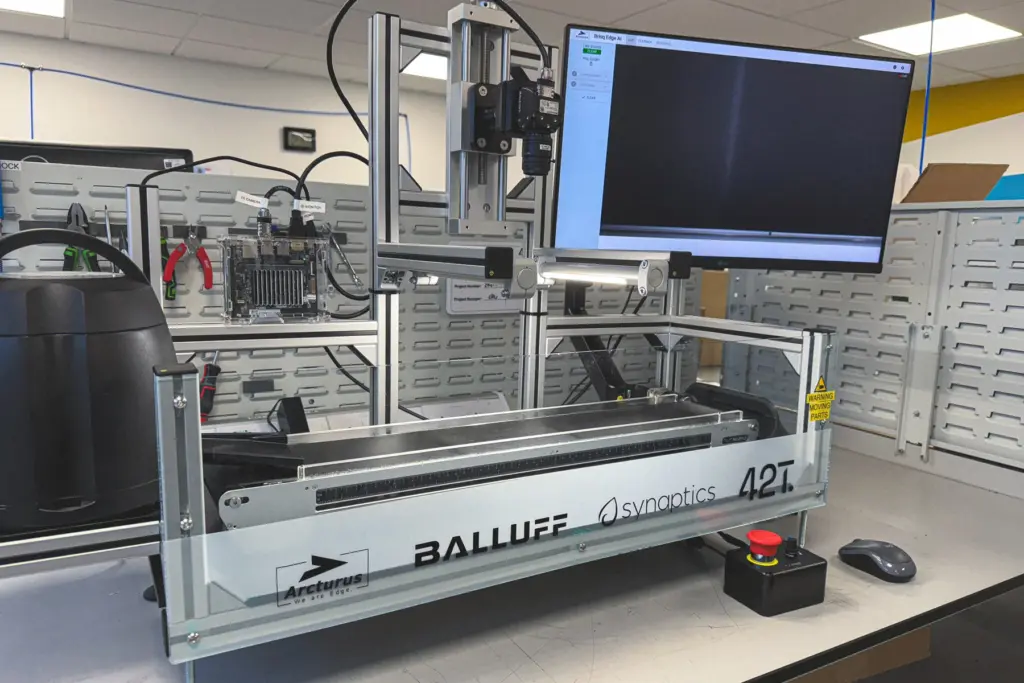

42T has designed and built a technology demonstrator to showcase this new AI-driven system in action. It will be launched at this year’s Embedded World event in Nuremberg, Germany (11 to 13 March) at the Synaptics booth (Hall 4A, #259). It will feature at several other major industry and customer events throughout 2025.

The new AI-powered approach combines Balluff’s high-performance image acquisition system with Arcturus’s deep-learning models and the Synaptics AstraTM SL1680 edge AI processor. The Astra SL-Series won Best in Show at last year’s Embedded World event for its exceptional AI capabilities, low power consumption and cost efficiency.

A key limitation of existing automated solutions is the need for extensive on-site training of their machine learning models at multiple points on live production lines. This new AI-powered platform eliminates that requirement by using deep learning as a stand-alone method for continuous model improvement. This creates a fully-automatic process where datasets are continuously developed in real time.

The system’s embedded intelligence compensates for variables such as shadows and changing light conditions, while its unique self-learning capability continuously improves accuracy and reliability during real-time operation to further boost production efficiencies for pharmaceutical manufacturers.

David Sandner, Product Marketing Manager for Machine Vision at Balluff said:

“With some pharmaceutical manufacturers operating up to 100 production lines with 20 or more cameras on each, cost and complexity have been major barriers to automating line clearance. Balluff is developing image acquisition and processing platforms to help customers and partners address these challenges in more cost-efficient ways. These solutions promise a real breakthrough in helping manufacturers to boost production efficiencies, save costs and increase security.”

42T and its partners have worked together to develop their breakthrough approach to target the cost and performance requirements of the pharmaceutical sector but it could also be used in other regulated industries such as medical devices, and food and beverage. The system uses fixed position cameras at key locations for monitoring, and is flexible enough to accommodate ‘pan and tilt’ cameras to scan different production areas depending on the application.

Synaptics’ SL Series is designed for high-volume, edge-AI IoT applications such as home and industrial control, smart appliances, digital signage, and displays. As an AI-native platform, designers can directly embed intelligence into the processor architecture to enable connected products with faster and more adaptive decision-making. This makes it the ideal solution for pharmaceutical manufacturers looking to integrate automated line clearance across multiple production lines.

White paper

A white paper on ‘Harnessing Edge AI vision system technology for automated line clearance in manufacturing‘ is also available on the 42 Technology website. This paper examines the challenges of manual line clearance, the limitations of existing automation solutions and how this new AI-driven approach delivers a cost-effective, scalable and high-performance solution for manufacturers. Download the full white paper to read more.

About 42 Technology

42 Technology (42T) is a product design and innovation consultancy, based near Cambridge (UK), that helps create technically advanced new products and enhanced manufacturing processes for some of the world’s best-known brands, as well as start-ups and SMEs. It works across five industry sectors: consumer, energy, medtech, life sciences, and industrial.

The company was founded in 1998 and has established a strong reputation for partnering with its clients to solve complex technical problems and develop brilliantly successful products. The team comprises engineers, scientists and designers, and offers a diverse range of skillsets that includes ethnographic research and usability engineering, product and system design, device testing and regulatory compliance.

42T is fully committed to innovation and sustainability at every stage: from generating its initial ideas and concepts for clients through to supporting them towards net-zero. It also has particular expertise in optimising manufacturing processes. For example to improve energy efficiencies, reduce waste, and to reconfigure existing production assets to accommodate sustainable materials or new product formats.

About Balluff, Synaptics and Arcturus Networks

Balluff is one of the world’s leading suppliers of high-quality sensors, identification and image processing solutions including network technology and software for all automation requirements. It is headquartered in Neuhausen a.d.F, near Stuttgart, Germany.

See balluff.com for more information.

Synaptics is leading the charge in AI at the Edge, bringing AI closer to end users and transforming how we engage with intelligent connected devices: at home, work, and on the move. It offers a range of ultra-low-power edge AI platforms, such as Astra AI-Native IoT processors, VerosTM wireless connectivity, and multimodal sensing solutions.

See synaptics.com for more information.

Arcturus Networks specialises in embedded software and hardware, and has in-depth expertise in edge AI smart cameras and vision sensors. The company is based in Toronto, Canada and provides expertise, experienced resources and IP to accelerate the development of edge systems for buildings, cities and industry.

See arcturusnetworks.com for more information.